Recognized By:

Intelligent Product Use Cases

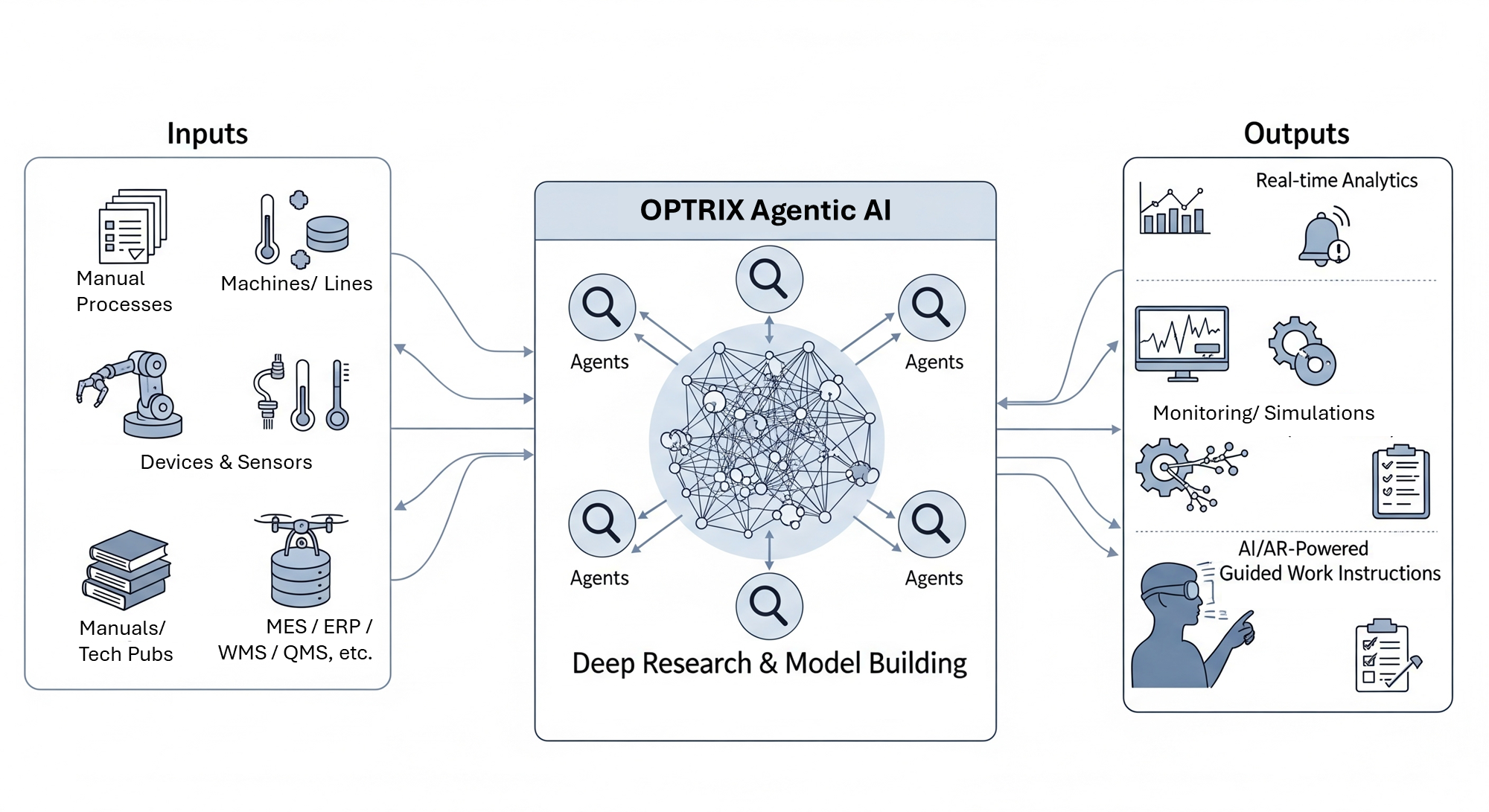

Industry-specific solutions powered by OPTRIX AI & AR

Self-optimizing process intelligence that improves continuously

Industry: Manufacturing & Pharma

Capability: Adaptive workflows with continuous optimization

Outcome: Operations that achieve new performance levels automatically

AR-guided maintenance operations with AI-powered training systems

Industry: Defense & Manufacturing

Capability: Expert knowledge transfer through immersive AR training

Outcome: Operations that prevent problems and train workers simultaneously

Real-time guidance from experts anywhere, anytime eliminating delays and improving uptime

Industry: Agnostic

Capability: Immediate access to expert knowledge through real-time collaboration

Outcome: No delays, minimal downtime, and improved productivity

AR-powered railway inspection and maintenance systems

Industry: Transportation & Infrastructure

Capability: Real-time safety monitoring with AR-guided inspection

Outcome: Operations that maintain critical rail infrastructure intelligently

Operational ResultsReal Impact, Measurable Outcomes

Organizations transforming operations through intelligent systems