Process compliance is an essential component of any business. It allows companies to operate at the highest level and ensure that they are meeting their customers’ expectations, while also complying with regulatory standards. In cold chain logistics, process compliance can be challenging due to the complex nature of temperature-controlled shipments and their importance in ensuring quality products arrive at their destination safely.

However, by understanding when and why noncompliance occurs (and how to address it), you can reduce losses, maximize efficiency and lower costs for your organization.

Process Compliance in Cold Chain Transportation

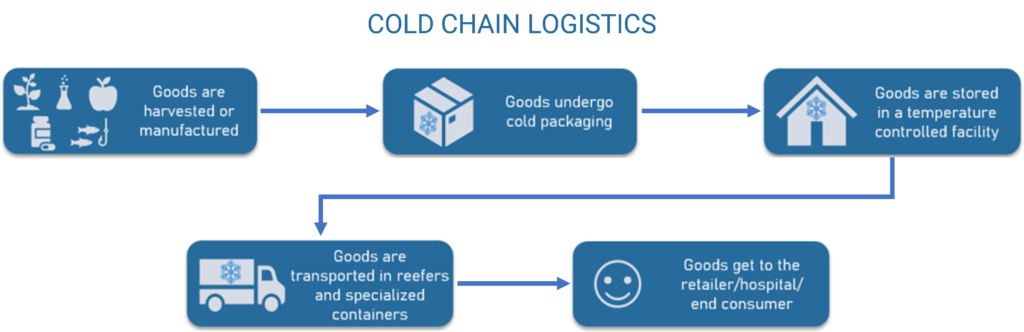

Process compliance is the foundation for minimizing losses, maximizing the effectiveness of cold chain transportation and reducing operational costs. Process compliance is a key element in the cold chain supply chain that helps ensure safe and effective handling of temperature sensitive products. However, process compliance is not just about following procedures — it’s about understanding how to do things right so as to prevent product losses due to poor handling practices.

Process compliance can be improved by implementing various technologies such as Digital Workflows for better data collection and process execution, RFID tags (Radio-frequency Identification), barcodes or QR codes for tracking products throughout their journey across various points within an organization; temperature sensors which provide real-time data on product temperatures at each location; video cameras which capture images from multiple angles so that any issues can be tracked; etc.

What Process Compliance Is and Why It Matters

Compliance is a set of rules, policies and procedures that help ensure the quality and safety of your products. It’s a key component of quality management systems (QMS) and helps to minimize losses, maximize the effectiveness of cold chain transportation and reduce operational costs.

Challenges to Process Compliance in Cold Chain Logistics

In the cold chain logistics industry, there are a number of challenges that can affect process compliance and ultimately lead to the degradation of products. The following are some examples:

- Poor training of personnel. Many workers do not have adequate knowledge about basic cold chain processes. This is evident from their inability to follow proper procedures, which may result in compromised product integrity.

- Poor communication between parties involved in transporting goods within a distribution chain or chain-of-custody (CoC). Inadequate communication often leads to issues such as mislabeled shipments, noncompliance with temperature requirements, and incomplete documentation on shipments containing perishable goods.

- Inadequate documentation on transportation processes used by individual companies or their suppliers or partners who participate in transporting goods within a distribution network—including third-party transportation providers like trucking companies—and/or cross-border shipments between countries/regions where different standards exist (e.g., Europe vs US). This lack of documentation is often due to poor communication between all parties involved along supply chains regarding transportation requirements specific for each product type being shipped; it also stems from poor planning amongst those carriers who provide services for clients without knowing what type(s) packages need protecting most urgently based on global climate conditions at given time frames (i.e., seasons).

Recommended Approach for Maintaining Process Compliance in Cold Chain Transportation

- Empower personnel with the right digital tools to manage and monitor process

- Leverage Guided Digital Workflows ensuring consistent process execution

- Integrate an IoT system to track & monitor temperature.

- Use a data management system to collect & store temperature data.

- Use machine learning to collect data, train and improve the process

- Use communication services to alert staff when temperature drops too low, or rises too high.

- Integrate and match data across disparate systems to automate validation checks

Process compliance is the foundation for minimizing losses, maximizing the effectiveness of cold chain transportation and reducing operational costs.

Process compliance is the foundation for minimizing losses, maximizing the effectiveness of cold chain transportation and reducing operational costs.

- The best way to ensure that a product meets its destination safely is by implementing a comprehensive process compliance program that includes:

- A clear understanding of what can go wrong in each step along the supply chain.

- An effective system of monitoring each step to detect problems before they occur.

- A defined set of corrective actions once a potential issue has been identified.

- Increased oversight of temperature regulation, compliance: https://www.foodlogistics.com/transportation/3pl-4pl/article/22432072/ta-services-3-benefits-modern-3pls-offer-refrigerated-freight-operations